Overview:

At Ragsdale Technology, we specialize in bridging the gap between traditional and emerging technologies. One of our recent projects involved helping a wood furniture manufacturer in Western Idaho stabilize and modernize their legacy systems without the cost of replacing critical software or equipment.

The Challenge:

The client’s operations relied on:

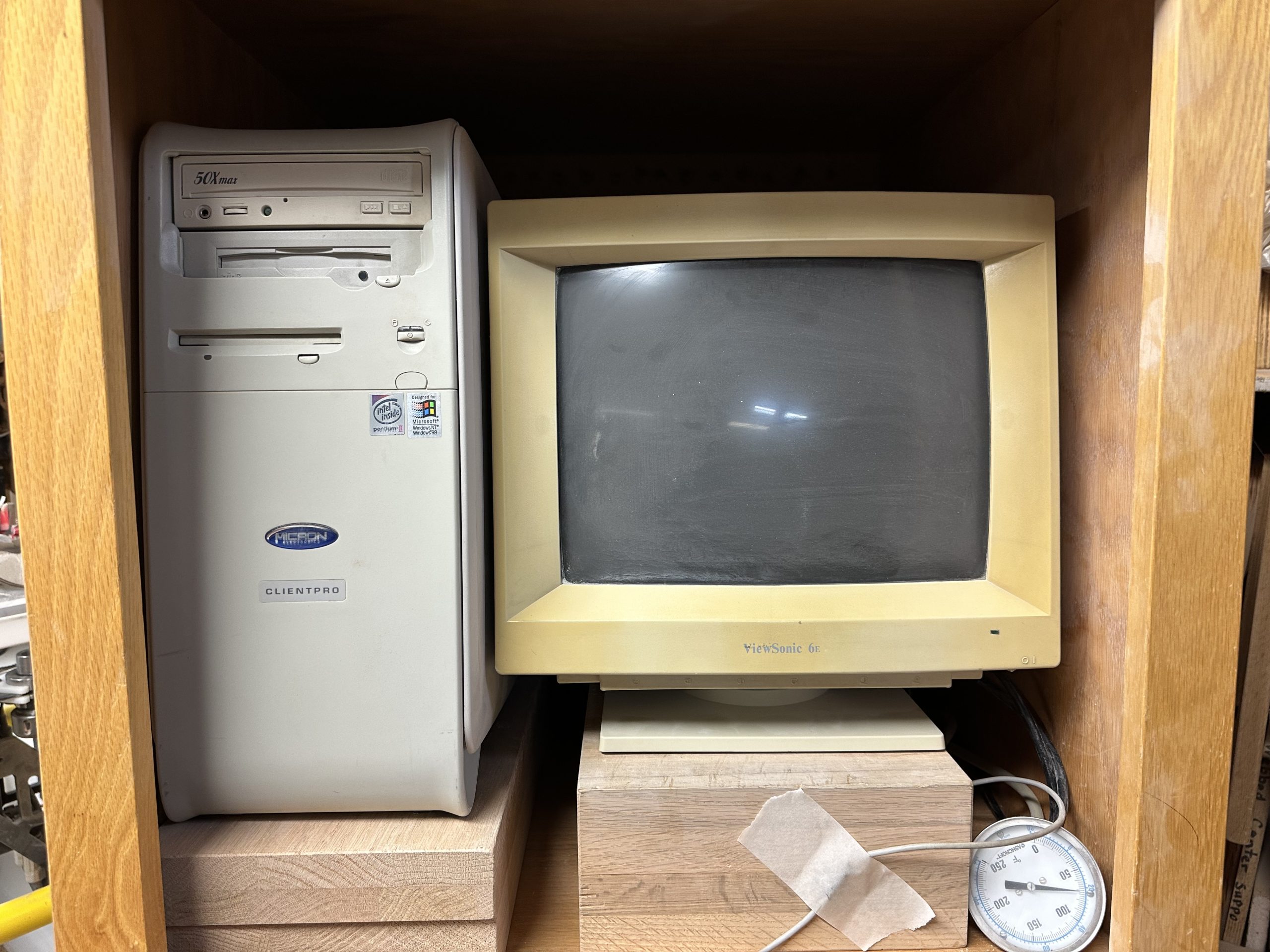

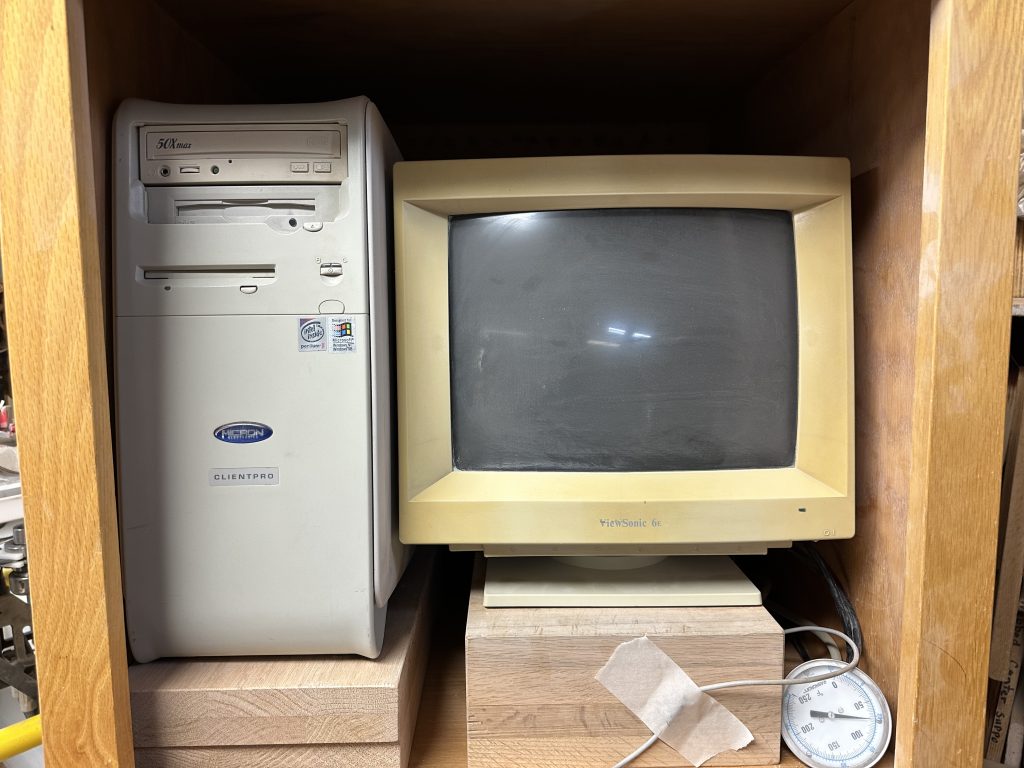

- A CNC machine running on Windows 95

- A draftsman workstation running Windows XP

- Legacy CAD software is critical for designing and manufacturing furniture

The aging hardware caused constant crashes, blue screens, and slowdowns. The aging hardware also caused issues with the potential of Backup/Disaster Recovery. Simply finding replacement parts was becoming untenable. Upgrading to modern machines wasn’t an option—their software simply wouldn’t run on new systems. The cost of upgrading to new software was estimated to be over $100,000, a cost that could not be rationalized by the client. On top of that, the environment introduced large amounts of heat, dust, and electrical interference.

Our Solution:

Ragsdale Technology designed and implemented a creative, cost-effective solution:

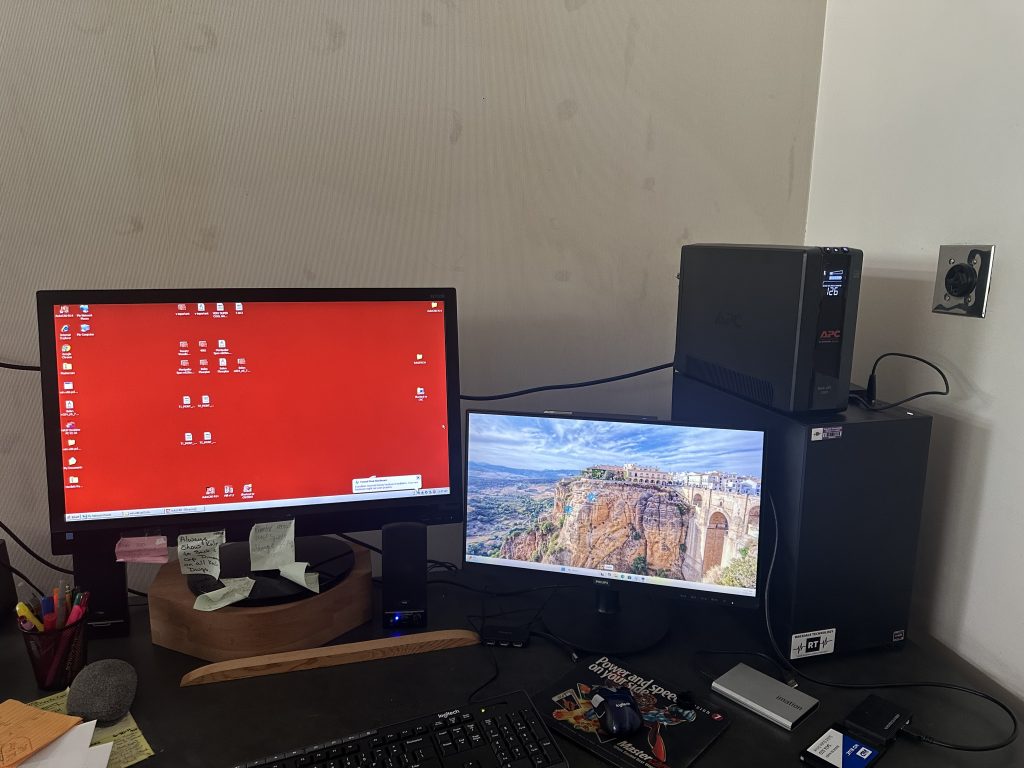

- Virtualization: We migrated the legacy Windows 95 and XP systems to a Proxmox-based virtualized environment on a secure, climate-controlled office server. The server was built out by Ragsdale Technology to allow for reliability and expandability while keeping cost constraints in consideration.

- Thin Clients: We replaced the old workstations at both the Drafting Desk and the CNC with modern thin clients, giving the client fast, reliable access to their virtual machines. Ragsdale Technology implores Ragsdale Tech VDI to allow for rapid and constant access to the VMs.

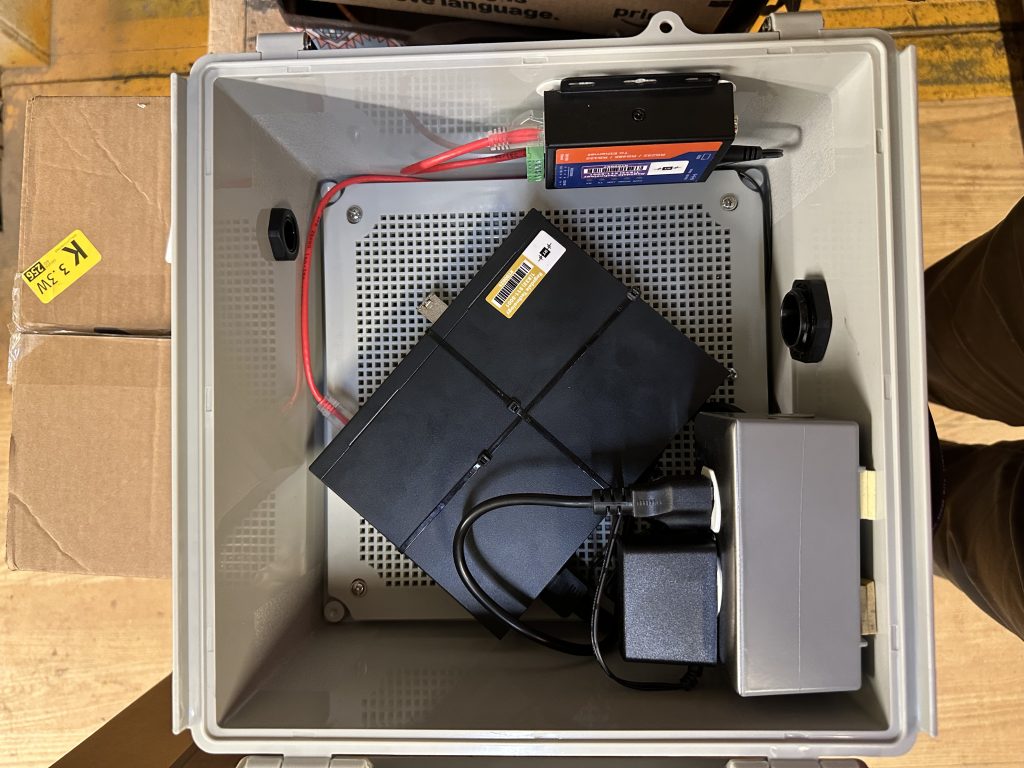

- Fiber Optic Networking: To bridge the long distance to the CNC machine and avoid interference from heavy equipment, we ran fiber optic cable across the plant to provide better connectivity.

- Centralized & Secure: Keeping the systems in a clean, temperature-controlled space extends equipment life and improves reliability. The centralized solution also allows for the simple execution of a recommended 3-2-1 backup solution.

We utilized weatherproof boxes to provide both environmental protection and mechanical protection of the switches and serial converter.

The Results:

- Zero crashes since deployment

- Faster, more stable performance for CAD and CNC operations

- Seamless communication between the virtualized systems and the CNC machine

- Improved productivity and morale—employees no longer waste time troubleshooting old PCs. The stress of wondering if mission-critical systems would turn on each day is gone.

The server was placed where the former Drafting computer used to live. We also ensured that the server would be protected from grid issues by placing it on a UPS.

Next Steps:

With their core systems stable and future-proofed, we’re now planning to virtualize and centralize their bookkeeping and sales systems for even greater efficiency and data security.

At Ragsdale Technology, we thrive on solving “impossible” IT problems—keeping legacy operations alive while preparing our clients for the future. We understand that not every business can or wants to upgrade systems.

Our approach ensures that organizations can keep doing what they do best, while we do what we do best: IT.

Ragsdale Technology is ready to become your trusted partner for IT growth and success. We would love to talk with you. Please reach out to us today.